G.Patton

Expert

- Joined

- Jul 5, 2021

- Messages

- 2,724

- Solutions

- 3

- Reaction score

- 2,878

- Points

- 113

- Deals

- 1

Distillation.

Distillation is evaporation of liquid with subsequent cooling and condensation of vapor. Distillation is considered first of all as technological process of separation and refining of multicomponent substances - in a number of other processes with phase transformation and mass transfer: sublimation, crystallization, liquid extraction and some others. A distinction is made between distillation with condensation of steam into liquid (in which the obtained distillate has an averaged composition due to mixing) and distillation with condensation of steam into solid phase (in which in the condensate there is a distribution of component concentration). The product of distillation is either a distillate or a residue (or both), depending on the substance being distilled and the purpose of the process. The main parts of the distillation device are a heated container (cube) for the liquid to be distilled, a cooled condenser (сondenser) and a heated steam line connecting them.

Simple distillation - partial evaporation of the liquid mixture by continuous removal and condensation of the resulting vapors in a refrigerator. The resulting condensate is called a distillate, and the unevaporated liquid is called a vat residue.

Fractional distillation (or fractional distillation) - separation of multicomponent liquid mixtures into different parts, fractions, by condensate collection by parts with different volatility, starting from the first, enriched with low boiling component. The remainder of the liquid is enriched with a high-boiling component. To improve fraction separation, a deflagmator is used.

Rectification is a method of distillation in which part of the liquid condensate (phlegm) is constantly returned to the vat, moving towards the steam in the column. As a result, the impurities contained in the steam partially pass into the phlegm and return to the vat, and the purity of the steam (and condensate) increases.

Fractional distillation (or fractional distillation) - separation of multicomponent liquid mixtures into different parts, fractions, by condensate collection by parts with different volatility, starting from the first, enriched with low boiling component. The remainder of the liquid is enriched with a high-boiling component. To improve fraction separation, a deflagmator is used.

Rectification is a method of distillation in which part of the liquid condensate (phlegm) is constantly returned to the vat, moving towards the steam in the column. As a result, the impurities contained in the steam partially pass into the phlegm and return to the vat, and the purity of the steam (and condensate) increases.

Applications.

The application of distillation can roughly be divided into four groups: laboratory scale, industrial distillation, distillation of herbs for perfumery and medicinal (herbal distillate), and food processing. The main difference between laboratory scale distillation and industrial distillation are that laboratory scale distillation is often performed on a batch basis, whereas industrial distillation often occurs continuously. In batch distillation, the composition of the source material, the vapors of the distilling compounds, and the distillate change during the distillation. In batch distillation, a still is charged (supplied) with a batch of feed mixture, which is then separated into its component fractions, which are collected sequentially from most volatile to less volatile, with the bottoms – remaining least or non-volatile fraction – removed at the end. The still can then be recharged and the process repeated.

In a drug manufacturing.

First, you can recover distilled solvents that were used in previous syntheses using distillation. This device helps you to significantly save on solvents and their utilization. This method allow purifying solvents, which were sold with non laboratory grades.

For example, in the amphetamine synthesis the solvents should be distilled. To purify acetone from contaminants (other solvents), the first distilled solvent fraction and the last distilled solvent fraction are removed during distillation.

Distillation is used in Synthesis of 5-Meo-Tryptamine from Melatonin during following stages:

The water layer was separated in a separatory funnel, and then the butanol was added back to the flask and set up for distillation. Half of the butanol was distilled off, until the liquid became very thick. On cooling, crystals were observed to form (freebase mexamine).

The recovered filtrate was concentrated by distillation, then diluted with acetone and placed in the freezer. The second crop of crystals was washed as before and weighed 7 g dry. The material was darker, and dull tan, and less crystalline than the first crop, but still of adequate purity to be used in the next step. To remove the colour, the recovered mexamine hcl can be recrystallized in isopropanol or ethanol. Total yield: 45 g

Distillation is used in a-PVP synthesis in the following stages:

8. Turn on reactor vacuum pump and chiller pump for reactor condenser.n9. Distilled all or most amount of ethyl acetate. 10. Stop vacuum pump and added in the reactor acetone. Stirring continues.

And obtaining diastereomer of a-PVP:

3. Extracted into Et2O, 50 ml.

4. Distilled Et2O.

Distillation, widely aplicate in laboratory practice and mentioned in Synthesis of ephedrine from propiophenone:

The aqueous layer is thrown out, organic extracts are combined, washed once with a weak solution of table salt and once with water, dichloromethane is distilled, preferably with reduced pressure.

In a drug manufacturing.

First, you can recover distilled solvents that were used in previous syntheses using distillation. This device helps you to significantly save on solvents and their utilization. This method allow purifying solvents, which were sold with non laboratory grades.

For example, in the amphetamine synthesis the solvents should be distilled. To purify acetone from contaminants (other solvents), the first distilled solvent fraction and the last distilled solvent fraction are removed during distillation.

Distillation is used in Synthesis of 5-Meo-Tryptamine from Melatonin during following stages:

The water layer was separated in a separatory funnel, and then the butanol was added back to the flask and set up for distillation. Half of the butanol was distilled off, until the liquid became very thick. On cooling, crystals were observed to form (freebase mexamine).

The recovered filtrate was concentrated by distillation, then diluted with acetone and placed in the freezer. The second crop of crystals was washed as before and weighed 7 g dry. The material was darker, and dull tan, and less crystalline than the first crop, but still of adequate purity to be used in the next step. To remove the colour, the recovered mexamine hcl can be recrystallized in isopropanol or ethanol. Total yield: 45 g

Distillation is used in a-PVP synthesis in the following stages:

8. Turn on reactor vacuum pump and chiller pump for reactor condenser.n9. Distilled all or most amount of ethyl acetate. 10. Stop vacuum pump and added in the reactor acetone. Stirring continues.

And obtaining diastereomer of a-PVP:

3. Extracted into Et2O, 50 ml.

4. Distilled Et2O.

Distillation, widely aplicate in laboratory practice and mentioned in Synthesis of ephedrine from propiophenone:

The aqueous layer is thrown out, organic extracts are combined, washed once with a weak solution of table salt and once with water, dichloromethane is distilled, preferably with reduced pressure.

Description.

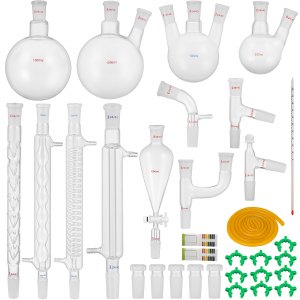

Laboratory display of distillation: 1: A heat source 2: Round bottomed flask 3: Still head (Würz flask) 4: Thermometer/Boiling point temperature 5: Condenser 6: Cooling water in 7: Cooling water out 8: Distillate/receiving flask 9: Vacuum/gas inlet 10: Still receiver 11: Heat control 12: Stirrer speed control 13: Stirrer/heat plate 14: Heating (Oil/sand) bath 15: Stirring mechanism (not shown) e.g. boiling chips or mechanical stirrer 16: Cooling bath.

Assembling.

Chemical coolers can be used either as reverse or downward (differ in the position and method of fixing when installing the device). The upper part of the condenser 5 is connected to a Würz flask 3, a Würz head or a tube extending from the flask containing the original mixture 2. The lower part is connected to the allonge 10, through which the product of synthesis or distillation enters the receiver 8. The cooling agent (water) is supplied exclusively from 6 the bottom up 7. If the condenser 5 is fed from top to bottom, the condenser jacket will not fill completely, making the cooling ineffective. In addition, with such a supply, the condenser may fail (crack) due to local overheating of the shirt. It is necessary to constantly monitor that the circulation of water through the condenser jacket does not stop, as switching off the condenser can lead to fires and explosions.

Assembling.

Chemical coolers can be used either as reverse or downward (differ in the position and method of fixing when installing the device). The upper part of the condenser 5 is connected to a Würz flask 3, a Würz head or a tube extending from the flask containing the original mixture 2. The lower part is connected to the allonge 10, through which the product of synthesis or distillation enters the receiver 8. The cooling agent (water) is supplied exclusively from 6 the bottom up 7. If the condenser 5 is fed from top to bottom, the condenser jacket will not fill completely, making the cooling ineffective. In addition, with such a supply, the condenser may fail (crack) due to local overheating of the shirt. It is necessary to constantly monitor that the circulation of water through the condenser jacket does not stop, as switching off the condenser can lead to fires and explosions.

Condensers are an important part of distillation. Types of condensers:

Straight cooler (downward) - used to condense vapors and remove the resulting condensate from the reaction system. The collection of condensate is carried out in a receiving flask;

Reflux condenser - used to condense vapors and return condensate to the reaction mass. Such refrigerators are usually installed vertically.

Reflux condensers are used when carrying out the reaction at the boiling point of the reaction mixture, but without distilling off the liquid; they provide for the condensation of vapors and the condensate draining back into the reactor along the walls of the refrigerator. Dephlegmator - a condenser for partial condensation of a light part of steam, reflux.

The simplest type of laboratory condenser is an air condenser, which is typically just a glass tube that is cooled by ambient air. It is used exclusively in working with high-boiling liquids (preferably with a boiling point of at least 300 °C), which, when working with a water cooler, due to the large temperature difference, could crack in the glass of the refrigerator.

Liebig condenser.

It is used mainly as a downward flow to about 160 °C. The cooling agent for substances with a boiling point of less than 120 °C is running water, and in the range of 120-160 °C it is non-flowing. The Liebig condenser consists of two glass tubes sealed one into the other. Liquid vapors move along the inner tube, and a cooling agent (cold water) moves along the outer (jacket). As a reverse, such a condenser is ineffective, since it has a small cooling surface and a laminar vapor flow; for this purpose it is used for high-boiling compounds (boiling point over 100 °C) compounds. Atmospheric moisture condenses on the outer surface of the condenser through capillary leaks. It is also recommended putting on a cuff made of dry filter paper on the refrigerator above the section. Higher boiling liquids at the junction can cause internal stress, causing the glass to crack. Therefore, Liebig condenser cannot be made of non-heat-resistant glass.

Reflux condenser - used to condense vapors and return condensate to the reaction mass. Such refrigerators are usually installed vertically.

Reflux condensers are used when carrying out the reaction at the boiling point of the reaction mixture, but without distilling off the liquid; they provide for the condensation of vapors and the condensate draining back into the reactor along the walls of the refrigerator. Dephlegmator - a condenser for partial condensation of a light part of steam, reflux.

The simplest type of laboratory condenser is an air condenser, which is typically just a glass tube that is cooled by ambient air. It is used exclusively in working with high-boiling liquids (preferably with a boiling point of at least 300 °C), which, when working with a water cooler, due to the large temperature difference, could crack in the glass of the refrigerator.

Liebig condenser.

It is used mainly as a downward flow to about 160 °C. The cooling agent for substances with a boiling point of less than 120 °C is running water, and in the range of 120-160 °C it is non-flowing. The Liebig condenser consists of two glass tubes sealed one into the other. Liquid vapors move along the inner tube, and a cooling agent (cold water) moves along the outer (jacket). As a reverse, such a condenser is ineffective, since it has a small cooling surface and a laminar vapor flow; for this purpose it is used for high-boiling compounds (boiling point over 100 °C) compounds. Atmospheric moisture condenses on the outer surface of the condenser through capillary leaks. It is also recommended putting on a cuff made of dry filter paper on the refrigerator above the section. Higher boiling liquids at the junction can cause internal stress, causing the glass to crack. Therefore, Liebig condenser cannot be made of non-heat-resistant glass.

Ball (Allihn) condenser.

Used solely as a reverse. Since this condenser has spherical expansions, the vapor flow becomes turbulent in it; the cooling effect of such a refrigerator is significantly higher than that of a Liebig condenser. However, atmospheric moisture also condenses on its outer surface and the junction is also dangerous. The cooling agent is supplied from bottom to top. It is convenient to insert the stirrer axis through the ball cooler, introduce various substances into the reactor, which are well washed off into the flask by condensate and heated by it. Typically, the number of balls in such condenser ranges from 3 to 8. To avoid flooding, when condensate does not have time to drain back into the flask with boiling liquid, the reflux condenser is installed in an inclined position, but the slope should not be too great so that condensate does not accumulate in the balls. The accumulation of condensation leads to a decrease in the effective cooling surface of the refrigerator.

Used solely as a reverse. Since this condenser has spherical expansions, the vapor flow becomes turbulent in it; the cooling effect of such a refrigerator is significantly higher than that of a Liebig condenser. However, atmospheric moisture also condenses on its outer surface and the junction is also dangerous. The cooling agent is supplied from bottom to top. It is convenient to insert the stirrer axis through the ball cooler, introduce various substances into the reactor, which are well washed off into the flask by condensate and heated by it. Typically, the number of balls in such condenser ranges from 3 to 8. To avoid flooding, when condensate does not have time to drain back into the flask with boiling liquid, the reflux condenser is installed in an inclined position, but the slope should not be too great so that condensate does not accumulate in the balls. The accumulation of condensation leads to a decrease in the effective cooling surface of the refrigerator.

Grahams condenser.

A Graham or Grahams condenser has a coolant-jacketed spiral coil running the length of the condenser, serving as the vapor–condensate path. This is not to be confused with the coil condenser. The coiled condenser tubes inside will provide more surface area for cooling and for this reason it is most favorable to use, but the drawback of this condenser is that as the vapors get condensed, it tends to move them up in the tube to evaporate which will also lead to the flooding of solution mixture. It may also be called Inland Revenue condenser due to the application for which it was developed.

A Graham or Grahams condenser has a coolant-jacketed spiral coil running the length of the condenser, serving as the vapor–condensate path. This is not to be confused with the coil condenser. The coiled condenser tubes inside will provide more surface area for cooling and for this reason it is most favorable to use, but the drawback of this condenser is that as the vapors get condensed, it tends to move them up in the tube to evaporate which will also lead to the flooding of solution mixture. It may also be called Inland Revenue condenser due to the application for which it was developed.

Dimroth's condenser.

A very efficient reflux condenser. It is also used as a downstream if the relatively large losses of distillate in the coil can be neglected. The junction of the jacketed coil A is outside the zone with a large temperature difference, therefore, using such a refrigerator when working with liquids boiling above 160 °C, you can not be afraid of complications. Since the outer jacket of the refrigerator is air at room temperature, atmospheric moisture does not condense on its surface. Low-boiling substances can "crawl" along the inner side of the jacket and thereby "drag" the cooling zone. The Dimroth condenser is therefore not suitable as a reverse for relatively low boiling substances such as ether. At the upper open end of the condenser, atmospheric moisture easily condenses on the water supply hoses, so it is supplied with a calcium chloride tube.

A very efficient reflux condenser. It is also used as a downstream if the relatively large losses of distillate in the coil can be neglected. The junction of the jacketed coil A is outside the zone with a large temperature difference, therefore, using such a refrigerator when working with liquids boiling above 160 °C, you can not be afraid of complications. Since the outer jacket of the refrigerator is air at room temperature, atmospheric moisture does not condense on its surface. Low-boiling substances can "crawl" along the inner side of the jacket and thereby "drag" the cooling zone. The Dimroth condenser is therefore not suitable as a reverse for relatively low boiling substances such as ether. At the upper open end of the condenser, atmospheric moisture easily condenses on the water supply hoses, so it is supplied with a calcium chloride tube.

Instruction.

For separation of liquids boiling below 150 °C at 1 atm from

1. nonvolatile impurities.2. another liquid boiling 25 °C higher than the first liquid. They must dissolve in each other.

Sources of Heat

If one of the components boils below 70 °C, and you use a Bunsen burner, you may have a hard time putting out the fire. Use a steam bath or a heating mantle. Different distillations will require different handling. This goes for enlightenment on the use of boiling stones and clamps as well.

Würz nozzle.

If there is anyone place your setup will fall apart, here it is. When you set up the jointware, it is important that you have all the joints line up. This is tricky, since, as you push one joint together, another pops right out. All joints must be tight!

Würz nozzle.

If there is anyone place your setup will fall apart, here it is. When you set up the jointware, it is important that you have all the joints line up. This is tricky, since, as you push one joint together, another pops right out. All joints must be tight!

The Distilling Flask.

Fill the distilling flask with the liquid you want to distill. You can remove the thermometer and thermometer adapter, fill the flask using a funnel, then put the thermometer and its adapter back in place.

Don’t fill the distilling flask more than half full. Put in a boiling stone if you haven’t already. These porous little rocks promote bubbling and keep the liquid from superheating and flying out of the flask. This flying around is called bumping. NEVER drop a boiling stone into hot liquid, or you may be rewarded by having your body soaked in the hot liquid as it foams out at you.

Make sure all the joints in your setup are tight. Start the heat slowly until gentle boiling begins and liquid starts to drop into the receiving flask at the rate of about 10 drops per minute. This is important. If nothing comes over, you’re not distilling, merely wasting time. You may have to turn up the heat to keep material coming over.

The Thermometer.

Make sure the entire thermometer bulb is below the sidearm of the 3-way adapter. If you don’t have liquid droplets condensing on the thermometer bulb, the temperature you read is nonsense. Keep a record of the temperature of the liquid or liquids that are distilling. It’s a check on the purity. Liquid collected over a 2 °C range is fairly pure.

The Condenser.

Always keep cold water running through the condenser, enough so that at least the lower half is cold to the touch. Remember that water should go in the bottom and out of the top. Also, the water pressure in the lab may change from time to time and usually goes up at night, since little water is used then. So, if you are going to let condenser cooling water run overnight, tie the tubing on at the condenser and the water faucet with wire or something. And if you don’t want to flood out the lab, see that the outlet hose can’t flop out of the sink.

The Vacuum Adapter.

It is important that the tubing connector remain open to the air or else the entire apparatus will, quite simply, explode.

WARNING: Do not just stick the vacuum adapter on the end of the condenser and hope that it will not fall off and break.

The Receiving Flask

The receiving flask should be large enough to collect what you want. You may need several, and they may have to be changed during the distillation. Standard practice is to have one flask ready for what you are going to throw away and others ready to save the stuff that you want to save.

The Ice Bath (if you need)

Why everyone insists on loading up a bucket with ice and trying to force a flask into this mess, I’ll never know. How much cooling do you think you’re going to get with just a few small areas of the flask barely touching ice? Get a suitable receptacle—a large beaker, enameled pan, or whatever. It should, not leak. Put it under the flask. Put some water in it. Now add ice. Stir.

Fill the distilling flask with the liquid you want to distill. You can remove the thermometer and thermometer adapter, fill the flask using a funnel, then put the thermometer and its adapter back in place.

Don’t fill the distilling flask more than half full. Put in a boiling stone if you haven’t already. These porous little rocks promote bubbling and keep the liquid from superheating and flying out of the flask. This flying around is called bumping. NEVER drop a boiling stone into hot liquid, or you may be rewarded by having your body soaked in the hot liquid as it foams out at you.

Make sure all the joints in your setup are tight. Start the heat slowly until gentle boiling begins and liquid starts to drop into the receiving flask at the rate of about 10 drops per minute. This is important. If nothing comes over, you’re not distilling, merely wasting time. You may have to turn up the heat to keep material coming over.

The Thermometer.

Make sure the entire thermometer bulb is below the sidearm of the 3-way adapter. If you don’t have liquid droplets condensing on the thermometer bulb, the temperature you read is nonsense. Keep a record of the temperature of the liquid or liquids that are distilling. It’s a check on the purity. Liquid collected over a 2 °C range is fairly pure.

The Condenser.

Always keep cold water running through the condenser, enough so that at least the lower half is cold to the touch. Remember that water should go in the bottom and out of the top. Also, the water pressure in the lab may change from time to time and usually goes up at night, since little water is used then. So, if you are going to let condenser cooling water run overnight, tie the tubing on at the condenser and the water faucet with wire or something. And if you don’t want to flood out the lab, see that the outlet hose can’t flop out of the sink.

The Vacuum Adapter.

It is important that the tubing connector remain open to the air or else the entire apparatus will, quite simply, explode.

WARNING: Do not just stick the vacuum adapter on the end of the condenser and hope that it will not fall off and break.

The Receiving Flask

The receiving flask should be large enough to collect what you want. You may need several, and they may have to be changed during the distillation. Standard practice is to have one flask ready for what you are going to throw away and others ready to save the stuff that you want to save.

The Ice Bath (if you need)

Why everyone insists on loading up a bucket with ice and trying to force a flask into this mess, I’ll never know. How much cooling do you think you’re going to get with just a few small areas of the flask barely touching ice? Get a suitable receptacle—a large beaker, enameled pan, or whatever. It should, not leak. Put it under the flask. Put some water in it. Now add ice. Stir.

Vacuum distillation.

Vacuum distillation is distillation performed under reduced pressure, which allows the purification of compounds not readily distilled at ambient pressures or simply to save time or energy. This technique separates compounds based on differences in their boiling points. This technique is used when the boiling point of the desired compound is difficult to achieve or will cause the compound to decompose. Reduced pressures decrease the boiling point of compounds. Appropriate vacuum pumps described in this article.

Instruction.

a) Vacuum distillation setup, b) Apparatus connected to a vacuum trap and water aspirator. Arrows show direction of suction.

a) Applying grease to a joint, b) Adequately greased joint, c) Testing an aspirator's suction, d) Vacuum tubing attached to the vacuum adapter.

Prepare the Apparatus:

- Safety note: Inspect every piece of glassware to be used with the vacuum distillation, checking for stars, cracks, or other weaknesses in the glass, as these may allow for implosion when the pressure is reduced.

- A stir bar needs to be used for bump prevention. Boiling stones cannot be used with vacuum distillation as air trapped in the stone's pores is rapidly removed under vacuum, causing the stones to fail to produce bubbles.

- Although greasing is somewhat of a personal choice with simple and fractional distillations, all joints must be greased in vacuum distillations or the system will leak and fail to achieve a low pressure.

- Begin assembly of the apparatus near the vacuum source. If using a water aspirator, test to be sure that the aspirator works well, as some are more functional than others. To test an aspirator, apply thick vacuum hosing to the nub of the aspirator, turn on the water and feel for suction at the end of the hose with your finger.

- A Claisen adapter should be included in the apparatus, as solutions under vacuum tend to bump violently.

- Attach thick-walled tubing to the vacuum adapter on the distillation apparatus and connect to a vacuum trap. A trap suitable for a water aspirator is shown, but a more substantial trap cooled with dry ice and acetone should be used with a portable vacuum to prevent solvent vapors from degrading the oil pump.

- Connect the trap to the vacuum source (aspirator or vacuum pump). It is best to not bend or strain the tubing as much as is practical, as this may create a leak in the system.

- Insert a wood block or lab jack beneath the stirring plate to allow for lowering of the heat source when the distillation is complete.

a) Stir plate with wood block to allow for lowering of the apparatus, b) Active distillation, c) Insulating the Claisen and three-way adapters with foil.

Begin the Distillation:

- Before heating, turn on the vacuum source to begin reducing pressure inside the apparatus. There should not be a hissing sound, or else there is a leak in the system.

- The purpose of reducing the pressure before heating is for removal of very low-boiling liquids (e.g. residual solvent). If the system were heated at the same time, the low-boiling liquids might boil violently in the flask.

- If a manometer is available, take note of the pressure inside the apparatus. This may be used to predict the boiling point of the sample.

- When confident that the apparatus is adequately evacuated and any low-boiling compounds have been removed, begin heating the sample.

- If it is difficult to achieve more than a reflux, the Claisen and three-way adapter can be insulated by wrapping them tightly with glass wool then aluminum foil. Insulation allows the column to maintain heat and the sample to remain in the gas phase longer. A small gap should be left in the insulation near the distilling flask to "peek in" and make sure the stirring mechanism continues to work properly.

- Record the temperature over which material is collected, making sure the value corresponds to a temperature when the thermometer bulb is fully immersed in vapors. If a manometer is used, also record the pressure. If no manometer is used, record the vacuum source (e.g. aspirator).

- Pure liquids do not always distill at a constant temperature when under vacuum, as variations in pressure so easily occur and affect the boiling temperature. A range of 5 oC is not uncommon for pure liquids. This is especially true when the vacuum source is a water aspirator, where variations in water flow alter the pressure.

- If more than one fraction of distillate is desired, the distillation must be stopped before changing the receiving flask. If available, a "cow" or "spider" receiving flask can be used to collect different fractions without ceasing the vacuum.

a ) "Cow" receiving flask for collecting multiple fractions: when a new fraction is distilling, the flask is rotated to allow for the distillate to collect into an empty section of the "udder", b) Cooling the flask with a tap water bath, c) Opening the vacuum on the trap before turning off the vacuum, d) Alternative way to open the apparatus before turning off the vacuum.

Stop the Distillation:

- To stop the distillation, first remove the heat source, cool the flask to room temperature, then further cool in a tap water bath.

- Slowly reinstate the atmospheric pressure into the flask by opening the pinch clamp at the vacuum trap, or by removing the rubber tubing at the vacuum adapter or aspirator. You will know the system is open to the atmosphere when there is an increase in water flow at the aspirator, or if a hissing sound is heard. Then turn off the vacuum source.

- It is important to first cool the system before allowing air back in, as the superheated residue in the flask may react unexpectedly with oxygen in the air.

- It is also important to first allow air back into the system before turning off the vacuum source. If the vacuum is turned off first, sometimes changes in pressure inside the apparatus (as it cools) cause back-suction. If a water aspirator is used, this may cause water from the sink to be pulled into the vacuum line. The vacuum trap prevents this back suction from ruining the distillate.

- Disassemble and clean up the distillation apparatus as quickly as is practical, as the joints can sometimes freeze if left connected for prolonged periods.

Safety.

Potential dangers arise from pressure buildup, commonly used flammable materials, and the use of heat to vaporize the chemicals involved. Careful design and construction of the distillation system is required to accomplish effective separation and avoid leaks that can lead to fires or contamination of the work area.

It is necessary to ensure smooth boiling during the separation process and avoid bumping, which can blow apart the distillation apparatus. Stirring the distillation mixture is the best method to avoid bumping. Boiling stones are only effective for distillations at atmospheric pressure. Use fresh boiling stones when a liquid is boiled without stirring. Do not add boiling stones or any other material to a liquid that is near its boiling point, because this may cause it to boil over spontaneously.

An electric mantle heater, a ceramic cavity heater, steam coils, or a nonflammable liquid bath are the best to provide even heating. Silicone oil or another suitable high-boiling-temperature oil can be used on a hot plate. Hot water or steam may also be used in some cases. An extra thermometer inserted at the center bottom of the distilling flask will warn of dangerously high temperatures that could indicate exothermic decomposition. Do not distill or evaporate organic compounds to dryness unless they are known to be free of peroxides.

Because superheating and bumping occur frequently during distillation using reduced pressure, it is important that the distillation assembly is secure, and the heat distributed more evenly than is possible with a flame. Evacuate the assembly gradually to minimize the possibility of bumping. Stirring, or using an air or nitrogen bleed tube, provides good vaporization without overheating and decomposition.

Put a standing shield in place for protection in the event of implosion. After finishing a reduced-pressure distillation, cool the system, and then slowly bleed in air, so as not to induce an explosion in a hot system. Pure nitrogen is preferred to air, and can be used even before cooling the system. Use a face shield when working directly with a distillation unit.

It is necessary to ensure smooth boiling during the separation process and avoid bumping, which can blow apart the distillation apparatus. Stirring the distillation mixture is the best method to avoid bumping. Boiling stones are only effective for distillations at atmospheric pressure. Use fresh boiling stones when a liquid is boiled without stirring. Do not add boiling stones or any other material to a liquid that is near its boiling point, because this may cause it to boil over spontaneously.

An electric mantle heater, a ceramic cavity heater, steam coils, or a nonflammable liquid bath are the best to provide even heating. Silicone oil or another suitable high-boiling-temperature oil can be used on a hot plate. Hot water or steam may also be used in some cases. An extra thermometer inserted at the center bottom of the distilling flask will warn of dangerously high temperatures that could indicate exothermic decomposition. Do not distill or evaporate organic compounds to dryness unless they are known to be free of peroxides.

Because superheating and bumping occur frequently during distillation using reduced pressure, it is important that the distillation assembly is secure, and the heat distributed more evenly than is possible with a flame. Evacuate the assembly gradually to minimize the possibility of bumping. Stirring, or using an air or nitrogen bleed tube, provides good vaporization without overheating and decomposition.

Put a standing shield in place for protection in the event of implosion. After finishing a reduced-pressure distillation, cool the system, and then slowly bleed in air, so as not to induce an explosion in a hot system. Pure nitrogen is preferred to air, and can be used even before cooling the system. Use a face shield when working directly with a distillation unit.

Suppliers.

There are a lot of glass vendors, I would recommend SIMAX glass because it is less fragile and can serve much more than Chinese analogues. Nevertheless, you can find any affordable option in your location.

Last edited: